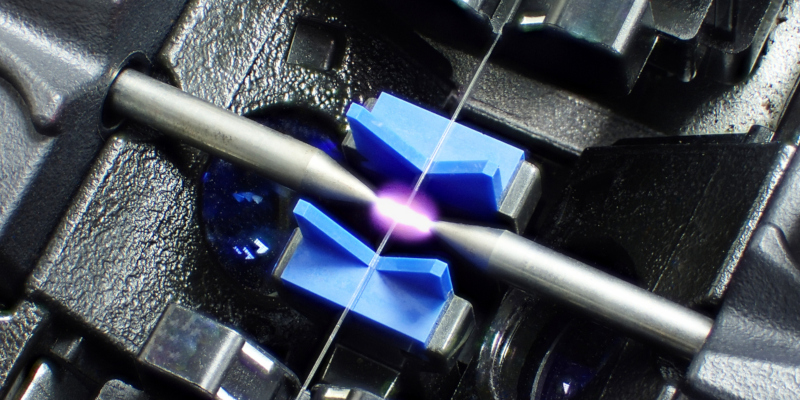

Splicing is a method in which several optical fiber cables are brought together end to end. Fiber optics splicing can be done in two ways. The first way is fusion splicing, where controlled heat is used to melt both ends of the fiber before welding them together. The second way is mechanical splicing, in which optic fibers are held inside a sleeve using a particular mechanical device.

Fusion splicing is a better technique for a couple of reasons:

- It Offers the Lowest Back Reflection

When compared to mechanical splicing, where the fibers are joined temporarily and accurately, fusion splicing provides little to no back reflection.

Back reflection, or reflectance, can affect fiber optic systems with several factors such as analog transmission and laser transmitters.

- It’s Ideal for Single-Mode Applications

In fiber optics splicing, fusion splicing is used in single-mode cables. These cables are used in CATV companies, universities, and others due to their ability to send signals further. Because of their minute diametrical core, applications allow a single mode of light to pass.

- It Offers a Safer Environment

Due to the firm join that it produces, it gives a safer and better environment that nullifies weak signals and failures from cables.

- It takes a Shorter Time to Do

Of the two techniques in fiber optics splicing, fusion splicing is the simpler to do. All you have to do is inspect the end of the fiber by removing the coating of both fibers. This also corrects cleaving. The fusion splicer does the rest.